S10 Track Mounted Screen

Introducing maximum unrivalled mobility & unique zero set up time. ‘’operating mode is transport mode’’.

The CDI S10 is fitted with an aggressive 2 bearing screenbox which can be adjusted in speed, amptitude and direction to suit all application needs for maximum efficiency.

Machine Weight: Approx. 1.9 Tonne (Basic Spec)

Output: Up to 40 TPH

Power unit: 15 Kw Diesel/Hydraulic (Onboard)

Tracks: 200mm (9”) wide Rubber

Discharge conveyor: 750mm wide (fully skirted)

Screenbox size: 1.52m x 0.9m (5’ x2’10”)

HT5 HD Tracked Vibrating Grid

Introducing Heavy Duty Hybrid technology for maximum output at minimum cost! The CDI Model HT5 has an onboard Heavy Duty Vibrating Grid. Its on-board conveyor stockpiles Screened Fines material. The machine is tracked and folded Via an on-board Diesel/Hydraulic Powerunit. The vibrating Grid and Discharge conveyor are Direct electric Driven and controlled by an onboard electric panel which is plugged into your 400V 3Phase Electric supply on site. This makes it Hybrid Electric giving you maximum screening efficiency with minimal power demand and wastage.

Machine weight: Circa 18Tonne (depending on build options)

Output: Up to 500TPH

Tracks: 400mm wide HD Steel shoes

Feed Height: 3.3m variable angle. Grid Feed Opening 4.6m x 2.45m.

Hopper Capacity 5Tonne. Belt width 1.2m.

(Also available in Fully Diesel/Hydraulic format if no site electric supply is available)

G40 Skid Mounted Vibrating Screen

The CDI G40 Stationary free standing skid mounted Screen is built to last with its Heavy Robust construction. It is designed to be fed directly by a standard Skid steer or wheel loader. It is fitted with an aggressive 2 bearing screenbox which can be adjusted in speed, amptitude and direction to suit all application needs to obtain maximum efficiency.

Machine Weight: Approx. 1.65 Tonne. (Basic Spec)

Electric drive system: (4kw single phase or 5.5kw 3 phase 50hz)

Output: Up to 200 TPH depending on material and application.

Inlet Feed height: 2.2m.

Inlet Feed width: 2.6m.

Screenbox size : 2.1m wide x 1.8m long inside. (Bi-Directional)

Mesh media size: 2 no 1.05m x 1.8m end tensioned mesh panels.

Mesh media types: Woven wire, Piano wire, Self Cleaning mesh and HD welded mesh.

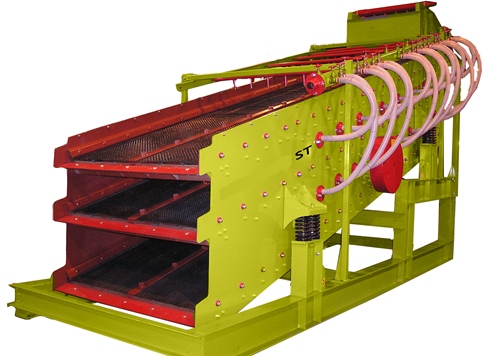

ST Stationary Bespoke Screens

Heavy Duty lasting build and High Precision Screening. The ST range is fitted with a Robust and Very Aggressive two bearing screening mechanism for High performance. All models come standard on a Robust Stepped chassis/subframe with HD ‘I’ beam construction to withstand high impact loads. The range offers Three model sizes spanning up to 5m Long with up to three integrated decks to obtain 4 grades of finished product.

The ST Range is ideally suited to rugged conditions in quarrying and mining environments where it can be integrated into the heart of any new or existing processing plant. Bespoke Chutes, structures and washing equipment are also available to suit any application. These special components are designed specifically to suit each individual application by the CDI Engineering Department. This service is available upon request .